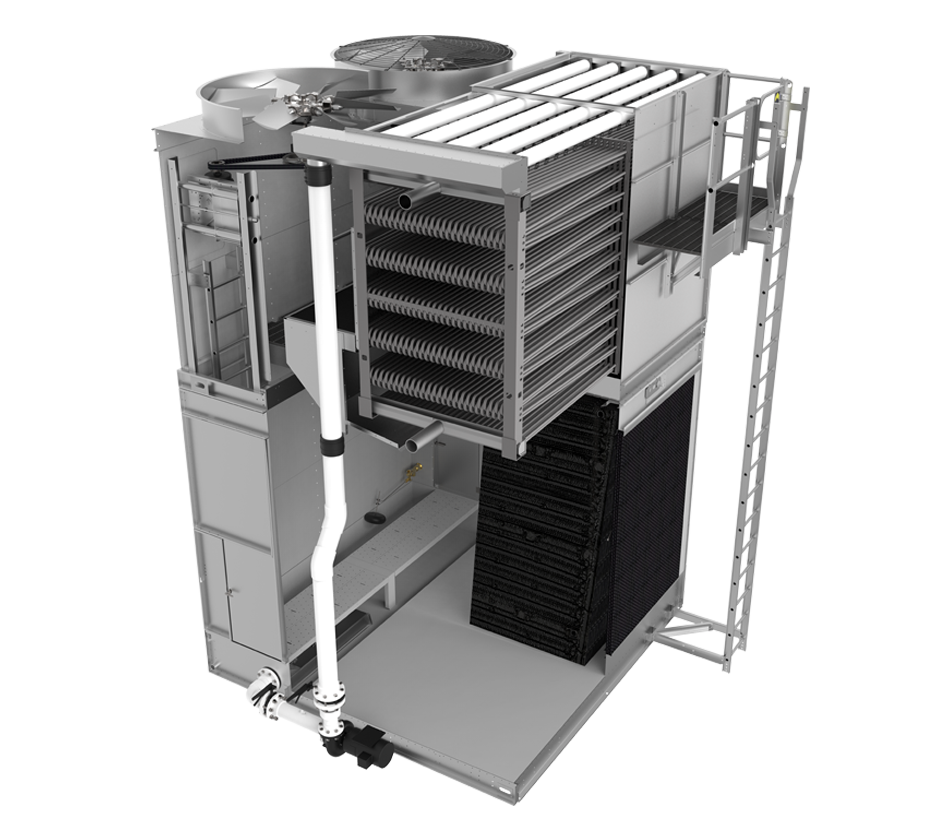

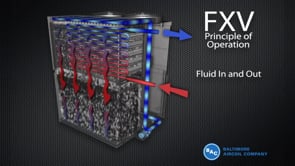

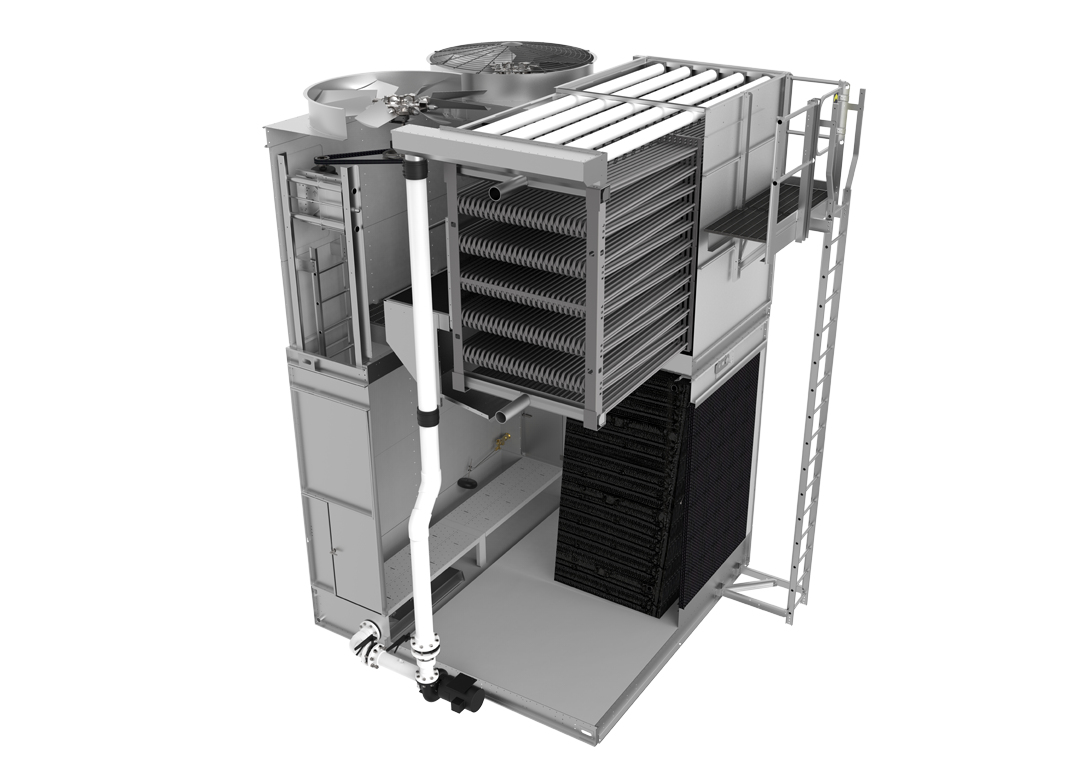

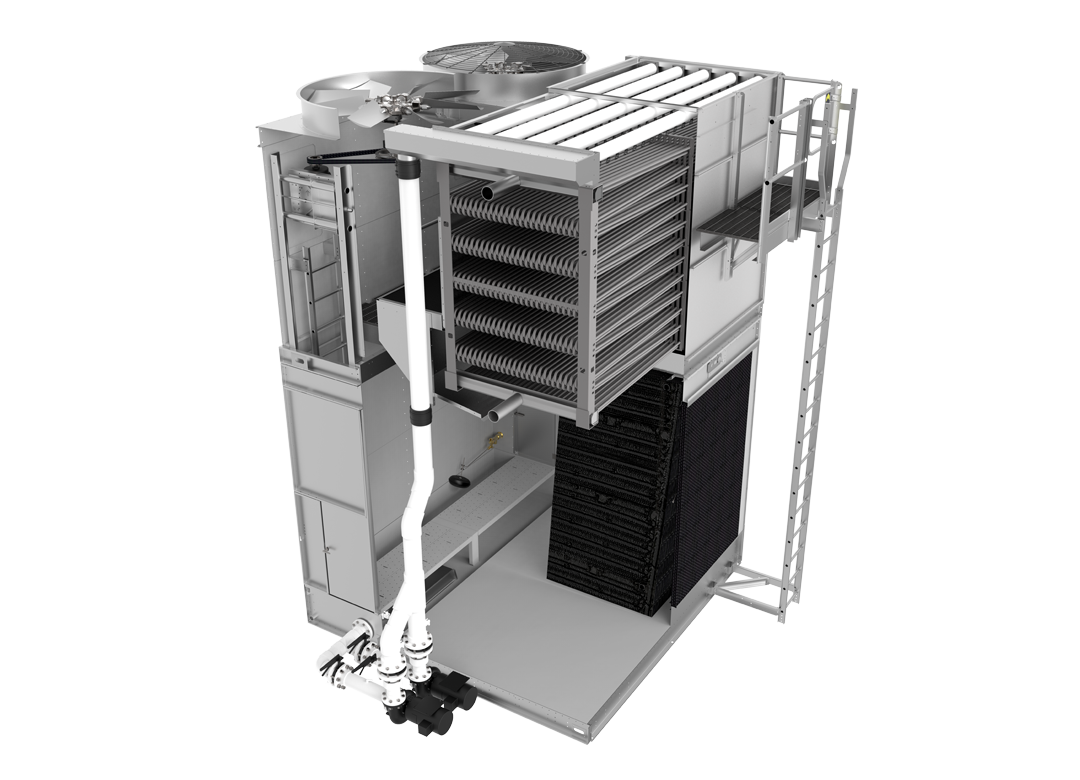

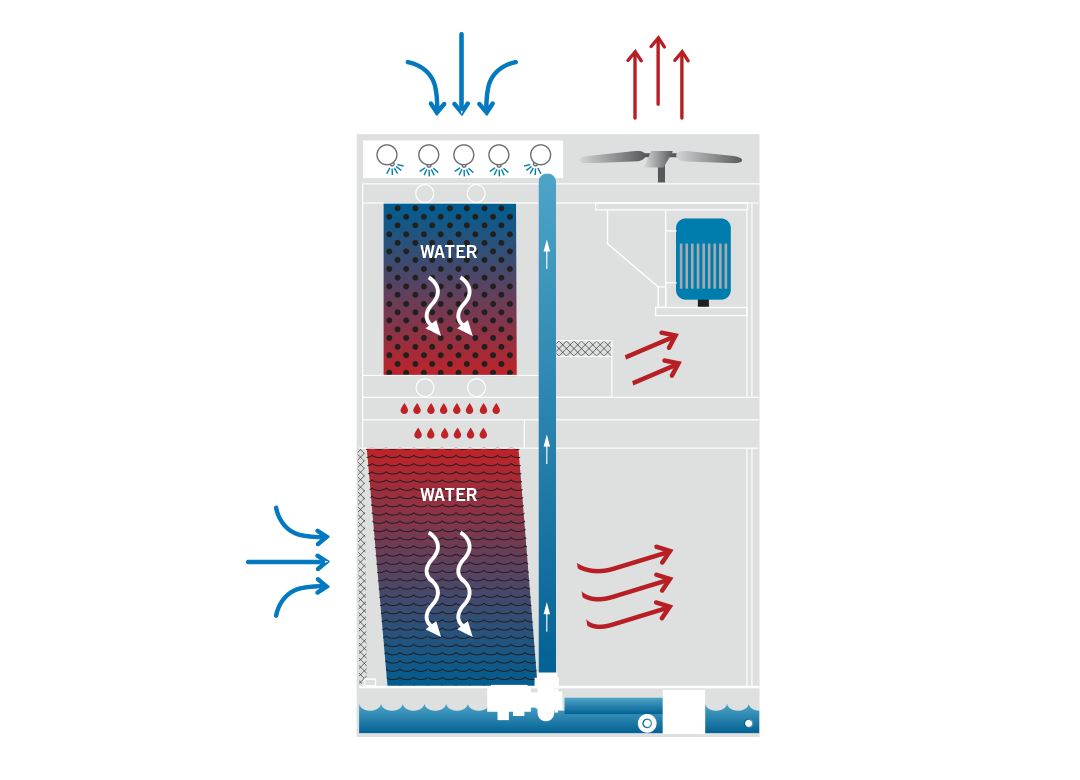

FXV Closed Circuit Cooling Tower

FXV - Construction and Operation

Learn about the FXV closed circuit cooling tower including its construction, features, and how it works.

Closed Loop Systems

In this webinar, BAC’s Frank Morrison and Andrew Rushworth review how closed loop cooling systems deliver many benefits compared to traditional open loop systems, such as reduced fouling, less risk of fluid contamination, and increased system reliability and uptime. Several methods can be used to “close the loop”, including the use of an open circuit cooling tower coupled with a plate & frame heat exchanger or the use of a closed circuit cooling tower, also called a fluid cooler.

BAC Leads the World in Heat Transfer Solutions

Discover BAC’s ongoing innovations in using the power of water to save energy in this segment of Inside the Blueprint that aired on Fox Business.

New and Innovative Ways to Reduce HVAC Operating Costs

This webinar will review recent developments and innovations in the evaporative cooling industry that guarantee reductions in HVAC energy and maintenance costs, while sustaining those energy efficiency gains over time. We will discuss how to apply these new technologies and examine new design strategies to optimize HVAC systems performance. These innovative technologies and design strategies will help design/consulting engineers, facilities managers, building owners and engineers find ways to reach new levels of energy efficiency, achieve lower maintenance costs and increase the reliability of your HVAC systems.

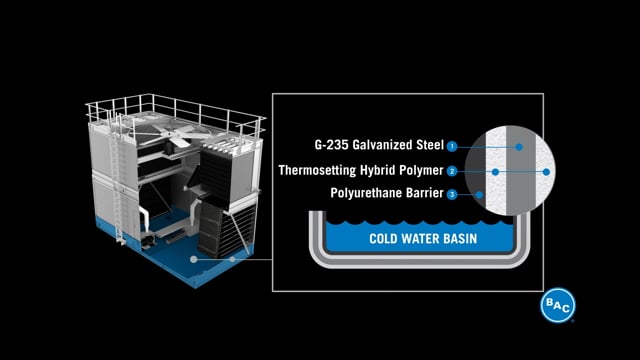

TriArmor® Corrosion Protection System

The TriArmor® corrosion protection system provides the ultimate cold water basin protection in the harshest environments. Watch this video to learn more.

Benefits

-

Energy

Energy -

Maintenance

Maintenance -

Installation

Installation -

Uptime

Uptime

Reduced Energy Usage

MAINTAIN PEAK SYSTEM EFFICIENCY WITH CROSSFLOW DESIGN

- Lower system energy costs with the combined crossflow design

- Reduce scale build up and ensure peak system energy efficiency with Combined Flow Technology

- Eliminate the need for field thermal performance testing costs with CTI Certification for both water and glycol

Key Resources

For new equipment, parts and inspection, or general inquiries, please fill out this form.