Immersion Cooling and Dielectric Fluids:

A Safe, Cost-Effective, and Low-Maintenance Solution for Modern Data Centers

As demand for data processing continues to climb, data centers are under pressure to increase performance while reducing energy use, maintenance costs, and environmental impact. In response, many operators are exploring alternative cooling technologies, and none have emerged as more promising than immersion cooling.

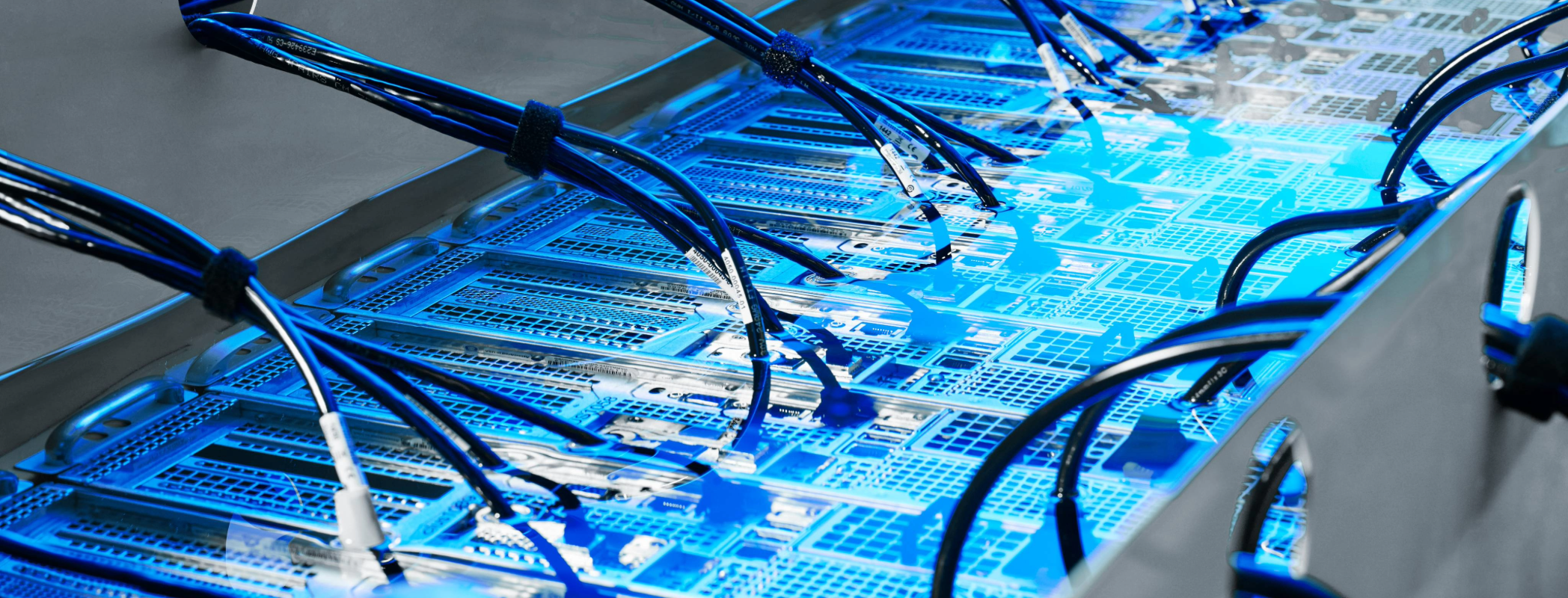

Unlike traditional air-cooled systems or even direct-to-chip liquid cooling, immersion cooling completely submerges servers directly into a dielectric fluid. This non-conductive, thermally stable liquid draws heat away from critical components such as CPUs and GPUs, efficiently transferring it to a secondary loop that rejects the heat outdoors via a cooling tower or fluid cooler. By eliminating air cooling entirely and improving thermal transfer efficiency, immersion cooling has the potential to radically reshape how data centers are operated.

At the heart of this innovation is the dielectric fluid itself. This specialized fluid is what enables submersion cooling to work safely, affordably, and with minimal maintenance. This article explores what makes dielectric fluids so effective and why more data centers are turning to them — in conjunction with immersion cooling — as the future of sustainable and reliable cooling.

Understanding Dielectric Fluids

Dielectric fluids are electrically non-conductive liquids with strong thermal transfer properties. Their ability to absorb and carry heat without conducting electricity makes them ideal for server immersion cooling, where they come into direct contact with server electronics. Common types of dielectric fluids include mineral oils, synthetic hydrocarbons, esters, and fluorocarbons. Each formulation has its advantages depending on application requirements, including temperature range, environmental impact, flammability, and material compatibility.

For data centers, the most desirable fluids combine excellent heat transfer capabilities with long-term material stability, low environmental risk, and minimal fire hazard. These fluids require little to no regular replacement, as they do not evaporate or degrade easily, which offers long-term cost savings and operational simplicity.

Safety First: Why Dielectric Fluids Are a Reliable Choice

A major concern for data center operators exploring immersion cooling is safety — particularly the risk of leaks, equipment damage, or fire. Fortunately, dielectric fluids are specifically designed with these risks in mind.

Non-conductivity is their most critical safety feature. Even in the event of an unlikely leak or accidental spillage, dielectric fluids are non-toxic, non-corrosive, chemically inert, and biodegradable.

Dielectric fluids can safely contact sensitive electronics and servers without causing equipment damage, unlike water based or glycol based coolants used in other systems.

Fire safety is another key advantage. Because many dielectric fluids are engineered to be fire-resistant and have low vapor pressures, they present a significantly lower fire risk than traditional air-cooled systems, which rely on high-speed fans and densely packed components.

In fact, well established chemical and oil companies have developed dielectric fluids with high flash points and low volatility, making them far less flammable than earlier generations of coolant oils.

The Cost Advantage: Efficiency That Pays Off

While switching to immersion cooling may seem like a major investment upfront, the long-term cost benefits of dielectric fluid systems are substantial. First, immersion cooling enables significantly higher heat transfer efficiency than air cooling. This leads to reduced reliance on energy-intensive chillers and HVAC systems.

According to estimates from Schneider Electric and other industry sources, data centers using immersion cooling can reduce cooling energy consumption by up to 90%. This translates into a major reduction in operating costs, especially as energy prices rise and sustainability goals become more aggressive.

Furthermore, dielectric fluids have long service lives. Many dielectric fluids on the market today are engineered to remain effective for 10 years or more with minimal degradation. That longevity dramatically reduces the total cost of ownership (TCO), especially when compared to fluids that require regular draining, filtering, or replacement. Because immersion systems also eliminate the need for air handling units, raised floors, and other infrastructure associated with traditional cooling methods, capital expenditures can be redirected to more efficient designs.

One of the most attractive features of dielectric fluid immersion systems is how little maintenance they require. Traditional air-cooled systems demand regular filter changes, fan inspections, airflow monitoring, and cleaning to prevent dust accumulation. In contrast, immersion cooling systems are largely self-contained. The closed-loop environment of the dielectric fluid bath protects internal components from contaminants like dust and debris, significantly extending equipment lifespan while reducing the need for cleaning.

Because of the fluid’s stability and resistance to evaporation, dielectric coolant levels stay consistent over time, further simplifying operations. There are fewer mechanical parts to service, fewer failure points, and fewer emergencies that require downtime or technician intervention.

For facilities with limited IT support staff or a desire to reduce maintenance workloads, immersion cooling using dielectric fluid provides a highly appealing path forward.

Promoting a Future-Ready Cooling Strategy

Immersion cooling with dielectric fluids also supports growing sustainability and ESG initiatives. Many fluids are biodegradable and designed with low toxicity profiles, reducing environmental impact both during use and at end-of-life disposal. The improved thermal efficiency of these systems also means less energy is used for cooling, resulting in lower greenhouse gas emissions. Some systems can also be paired with heat reuse infrastructure, repurposing waste heat for building heating or other applications—further enhancing their sustainability. Additionally, the reduced need for air handlers and HVAC equipment lowers the embodied carbon of data center construction and enables more compact facility footprints.

While many cooling strategies will continue to coexist depending on workload, climate, and facility type, immersion cooling represents a forward-looking solution that addresses key challenges across the board: heat density, operational efficiency, cost control, and environmental impact. The choice of dielectric fluid plays a central role in realizing these benefits. From synthetic esters to engineered hydrocarbons, modern dielectric fluids provide the safety, stability, and performance necessary to support long-term immersion cooling deployments.

As a leading provider of heat rejection and fluid cooling solutions, BAC is helping data centers make the leap to server immersion cooling by offering high-efficiency cooling systems designed to pair seamlessly with dielectric fluid-based technologies. BAC’s fluid coolers are engineered for low-maintenance operation and optimized for energy efficiency — a perfect match for the needs of immersion-cooled facilities. With a focus on sustainability, safety, and service, BAC is proud to support the data centers of tomorrow.