Case Study on Choosing Cooling Tower Replacement Fill

Baltimore Aircoil Company (BAC) is excited to announce the release of a new case study titled “Choosing Cooling Tower Replacement Fill” that highlights the clear differences in performance between block fill and BAC VersaCross® Replacement Fill.

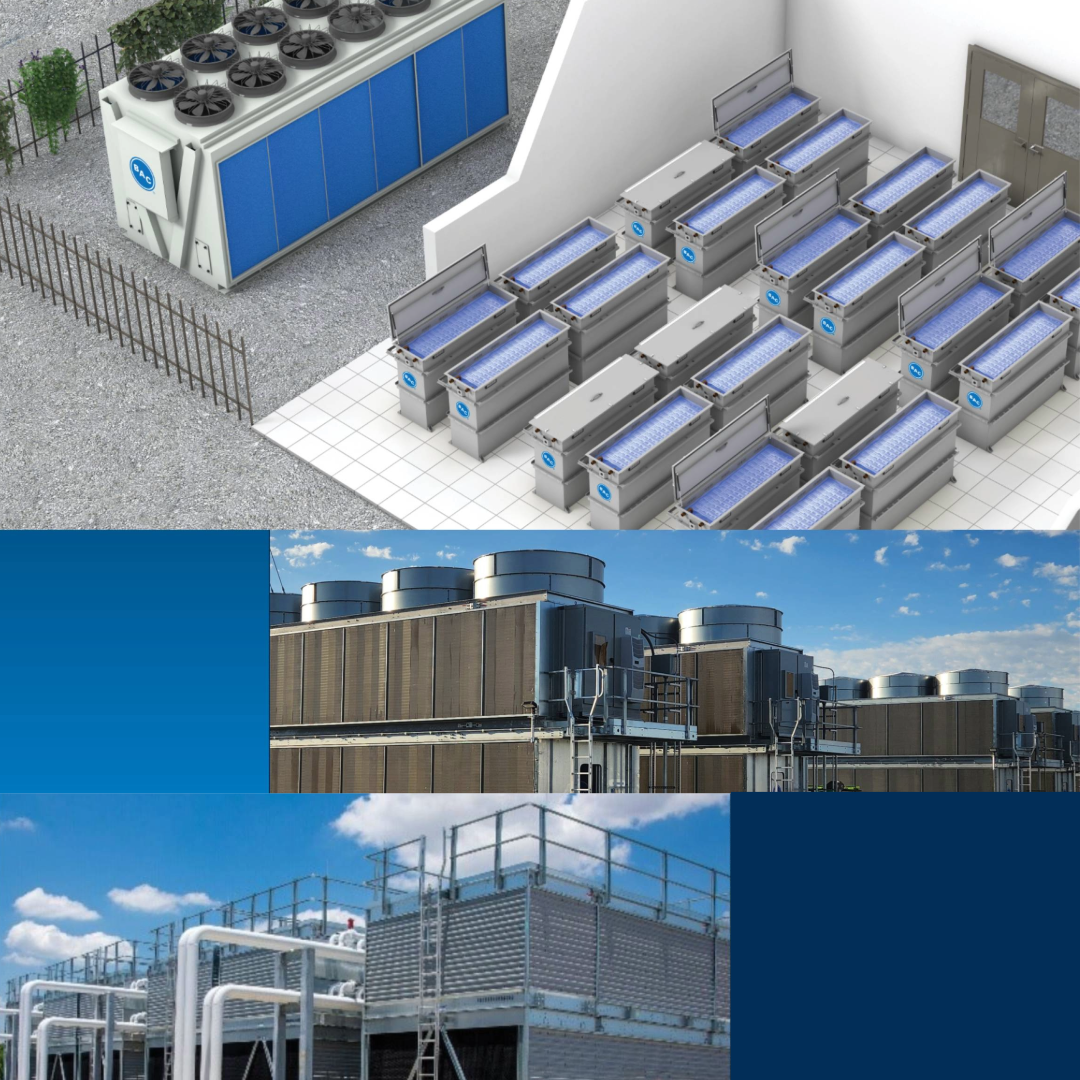

In this case study, a large professional sports arena in Southern California decided that the fill in its three BAC Series 3000 Cooling Towers with a crossflow design needed to be replaced as part of a long-term maintenance plan. They replaced the fill pack in one cooling tower per year over three years. The first two towers’ fill packs were replaced with BAC’s VersaCross® Replacement Fill, a “hanging” style fill that matched the fill originally installed. When it came time to replace the fill in the third tower, the building owner decided to use a competitive product, a “block” style fill.

After BAC raised concerns about the performance of the block fill, an independent testing company was assigned to conduct side-by-side tests comparing the performance of the cell with the block fill to the performance of one of the cells with the VersaCross® Fill. After the testing showed clear performance deficiencies of the block fill, the arena replaced it with BAC VersaCross® Fill.

The block fill may have had a lower initial purchase price, but it ended up costing more in energy consumption, maintenance costs, and short useful life than if the OEM replacement fill had been selected. The arena learned the hard way that the design and the quality of the fill is critically important to cost-effective, efficient, and reliable performance of the evaporative cooling tower.

To read the full case study, click here.